Ultrasonic welding is a highly versatile joining technology that eliminates the need for chemical solvents or adhesives and reduces energy consumption. It also aligns with modern sustainable manufacturing practices.

The ultrasonic generator converts electrical energy into mechanical vibrations at 20,000 Hz. This energy is transmitted to the plastic parts via the horn (sonotrode). Similar thermoplastics can be ultrasonically welded together, but dissimilar materials are able to fuse together only if their melting temperatures are close. Read on Ultrasonic Plastic Welding Machines Florida for more details.

Ultrasonic welding is a quick process that requires minimal preheating. When power is turned on, the machine generates frictional heat from the mechanical vibration of an oscillating horn that can entangle the polymer chains of two separate thermoplastic parts. The result is a strong, long-lasting bond.

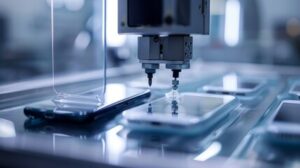

The process begins with arranging the workpieces to form a lap joint, then placing them on a welding stack, which is made up of the transducer assembly and a support tooling or fixture to hold the pieces in place during the welding cycle. The machine’s generator produces high-frequency electricity, which is converted to mechanical vibration by the converter. The resulting vibrations are amplified by the booster before being focused on the weld horn, which is designed to match the contours of the workpieces and amplify the energy of the mechanical vibration.

As the horn vibrates, it creates frictional heat, which enables the plastic to melt and then coalesce into a single solid piece of weld. This is achieved without the formation of a harmful heat-affected zone (HAZ) that can occur in other welding methods. The weld created by this process is typically 90-95 percent as strong as the two original plastics, and it does not require the use of fillers or binders to achieve strength.

To optimize the welding process, it is important to choose the right converter, booster and weld horn for the material you are working with. Each thermoplastic has a specific range of amplitude that will efficiently initiate melt. A mechanical vibration that is too high can cause premature melt and destruction of the materials, while a vibration that is too low will not produce sufficient weld force.

Other factors that can influence the performance of an ultrasonic welding process include mold release, moisture and chemical additives. For example, lubricants such as waxes and stearates can interfere with the fusion of thermoplastics. When a lubricant is present, it is necessary to remove it from the workpieces before attempting to weld them. Other additives, such as plasticizers, can reduce the weldability of plastics by reducing intermolecular friction and making the resins brittle.

Machines

A key benefit of ultrasonic plastic welding is that it does not require chemicals or solvents to seal parts together. In fact, most welds are made within a fraction of a second and only use pressure to hold the pieces in place. This allows you to increase production without sacrificing quality and creates a strong, hermetic seal that requires no additional materials such as glue, adhesives or mechanical fasteners.

In this process, high frequency electrical energy is converted into mechanical vibrations through a transducer. This vibration energy vibrates the parts that are to be welded, causing molecular friction between the parts which in turn generates heat. This frictional heat causes the plastics to melt, allowing the parts to be joined.

This weld technology can only be used with plastics that can be melted or shaped when heat is applied (thermoplastic materials). The resulting bond is created by cohesive or form-fit joints that are extremely strong and hermetic. This makes the process suitable for most applications including food packaging, medical devices and electronics.

RTUL is proud to offer a wide range of ultrasonic plastic welding machines for every application. From standard models to customized solutions, our team has the expertise and equipment you need to solve even your most challenging applications. Welding molded thermoplastics is our specialty. We can help you develop a system that will meet your production needs while staying within your budget.

To determine which ultrasonic plastic welding machine is right for your application, start by determining the size of the parts you need to weld. 15 kHz welding machines are typically used for larger parts, 20 kHz welders are appropriate for medium-sized parts and 40 kHz welders work well with smaller, delicate parts.

The next consideration is the chemical compatibility of the materials you need to join. This is determined by comparing the melt flow index (MFI) of the two materials you are using. The MFI is found in the manufacturer’s literature for each polymer and gives an indication of how easily the material will melt when exposed to heat. For best results, you should choose plastics with similar MFI’s.

Materials

Ultrasonic plastic welding is an alternative to using adhesives or direct heat application. Instead, this method of plastic bonding relies on sound waves to create the weld, which is then reinforced with pressure to form a strong and durable joint. The process is computer controlled, allowing for high rates of production and consistent results. It can also be used on a variety of different materials, including solid plastics, films and artificial products.

In order for this process to work, the plastic must be able to transmit the ultrasonic energy. This is determined by measuring its Melt Flow Index, or MFI. A high MFI indicates that the plastic is able to melt and flow when subjected to sufficient vibration. It is also important that the two pieces of plastic being welded have a similar MFI. Otherwise, they will not be able to join together properly.

Once the welding process begins, the ultrasonic vibrations cause molecules in the plastic to rapidly bind together and fuse. This makes the joint stronger and more durable than any other method of binding plastic parts. Moreover, this process is very fast and does not require the use of any adhesives or mechanical fasteners.

There are many different types of plastics that can be welded with this method, including ABS (acrylonitrile butadiene styrene), PS (polystyrene), SAN (polymethyl methacrylate), and PE (polyethylene). However, the best choice for your project depends on its specific needs. For example, some projects require plastics that are resistant to moisture, while others need to be very strong.

To perform ultrasonic plastic welding, a machine is required that generates and amplifies the vibrations. This is usually done with a horn, which is designed to match the shape of the part being welded to ensure effective energy transmission. A control system is also included to set welding parameters, such as time and pressure. Lastly, a cooling system is necessary to prevent overheating and maintain consistent performance. In addition, the machine should be placed on a stable workbench and left with adequate space behind it for ventilation and heat dissipation.

Applications

Unlike traditional welding methods, ultrasonic plastic welding does not require any external materials like adhesives or mechanical fasteners to bond parts together. This makes it a cleaner and faster process that’s ideal for high-volume production. It can also be used for complex geometries that might be challenging for other welding processes.

The process works by applying a controlled force to clamp the parts together against each other while the ultrasonic horn vibrates them at an extremely high rate, up to 40 thousand times per second at distances measured in thousands ofths of an inch (microns). Through careful machine and part design, the mechanical vibration energy can be focused on limited points of contact between the plastic parts. Once the energy has been directed, the horn is then stopped and the parts are held under pressure to allow them to cool and solidify.

The pressure helps to create a strong connection between the two parts and eliminates any potential defects or leakage. Once the welded connection has fully cooled, the part is removed from the machine and either moved to another station or placed into a bin for disposal. The welded connection is not only clean, but it’s also strong and reliable.

There are some limitations to the process, but with proper machine and part design, almost any thermoplastic can be bonded using ultrasonic plastic welding technology. It is important to consider the chemical compatibility of the materials and their moisture content, as this can affect the quality of the resulting weld. In general, it is best to use similar materials with a similar melt flow index (MFI) for the most effective results.

The welding process is very quick, with most bonded connections taking no more than three seconds to complete. This can make it an extremely efficient and cost-effective method for many applications, especially when compared to other weld processes such as induction or resistance heating. It is also very easy to control, with the ultrasonic frequency and duration both able to be precisely adjusted for optimal results. The lack of chemicals or dust created by the process also makes it suitable for use in a wide range of medical applications such as catheters, dialysis tubes, face masks and air filters.